Auto 52

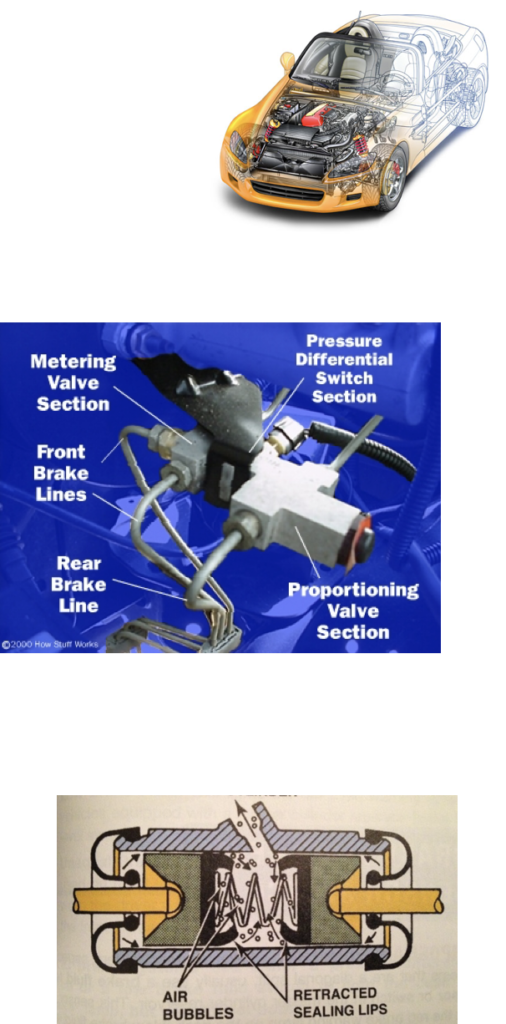

Automotive Brake Valves and Switches – The Metering Valve , Pressure Differential Switch, Residual Check Valve and Proportioning Valve Combined into one unit

Nick Rothman

City College of San Francisco • February 6, 2024

Metering Valve

The metering valve is required on cars that have disc brakes on the front wheels and drum brakes on the rear wheels. You know that the disc brake pad is normally in contact with the disc, while the drum brake shoes are normally pulled away from the drum. Because of this, the disc brakes are in a position to engage before the drum brakes when you push the brake pedal down.

The metering valve compensates for this, making the drum brakes engage just before the disc brakes. The metering valve does not allow any pressure to the disc brakes until a threshold pressure has been reached. The threshold pressure is low compared to the maximum pressure in the braking system, so the drum brakes just barely engage before the disc brakes kick in.

Having the rear brakes engage before the front brakes provides a lot more stability during braking. Applying the rear brakes first helps keep the car in a straight line, much like the rudder helps a plane fly in straight line.

Pressure Differential Switch

The pressure differential switch is the device that alerts you if you have a leak in one of your brake circuits. The valve contains a specially shaped piston in the middle of a cylinder. Each side of the piston is exposed to the pressure in one of the two brake circuits. As long as the pressure in both circuits is the same, the piston will stay centered in its cylinder. But if one side develops a leak, the pressure will drop in that circuit, forcing the piston off-center. This closes a switch, which turns on a light in the instrument panel of the car. The wires for this switch are visible in the picture above.

Proportioning Valve

The proportioning valve reduces the pressure to the rear brakes. Regardless of what type of brakes a car has, the rear brakes require less force than the front brakes.

The amount of brake force that can be applied to a wheel without locking it depends on the amount of weight on the wheel. More weight means more brake force can be applied. If you have ever slammed on your brakes, you know that an abrupt stop makes your car lean forward. The front gets lower and the back gets higher. This is because a lot of weight is transferred to the front of the car when you stop. Also, most cars have more weight over the front wheels to start with because that is where the engine is located.

If equal braking force were applied at all four wheels during a stop, the rear wheels would lock up before the front wheels. The proportioning valve only lets a certain portion of the pressure through to the rear wheels so that the front wheels apply more braking force. If the proportioning valve were set to 70 percent and the brake pressure were 1,000 pounds per square inch (psi) for the front brakes, the rear brakes would get 700 psi.

Residual Check Valve

The residual check valve is located in the outlet of the master cylinder. Its purpose is to maintain 10 -15 psi of pressure in the brake lines to the rear drum brakes. When the brake pedal is released the residual pressure keeps the wheel cylinder cup in contact with the wheel cylinder bore. Image shows how the sealing cups would retract and allow air into the hydraulic system without residual pressure to keep cups sealed to the wheel cylinder bore.