For an engine to run, it must have enough compression to raise the temperature of the air fuel mixture high enough so that a spark can easily start an efficient combustion process. Also the piston must seal to the cylinder to keep oil from going into the combustion chamber and burning. If there is low compression the engine will burn a lot of oil. If an engine has very low compression it will fail to start.

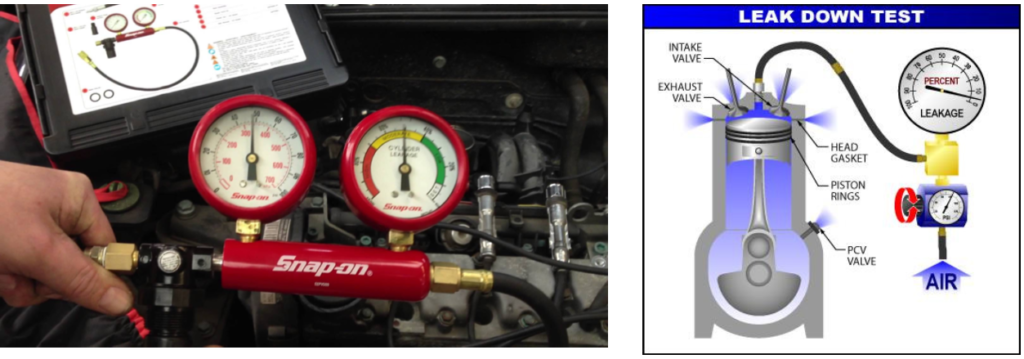

Engine compression is most accurately checked with a compression gauge. This test can take considerable time, especially when the spark plugs are difficult to remove. With this test you will know beyond doubt if there is low compression in one or more cylinders. The only downside is the time spent performing the test. On certain v-6 front wheel drive vehicles where spark plug access is difficult it could take 3 hours to perform a compression test on all cylinders. A Snap-on compression tester with adapters for various vehicle brands is shown below. To use this tool a rubber tube is installed into the spark plug hole. Then the compression gauge, which basically reads air pressure, is connected. The engine is cranked with the starter. If pressure is not created when the cylinder rises on the compression stroke we know there is a serious issue with the engine.

Remember that a compression test must be performed after the engine has been warmed up and all the spark plugs have been removed. A cold engine has lower compression because parts have not expanded, oil has not warmed up and reached various parts of the motor. The piston rings will not seal to the cylinder walls without an oil coating. One technique used when compression testing an engine that cannot be warmed up, like a used junk yard

engine is to pour a bit of motor oil into each cylinder through the spark plug holes before the compression test. Another challenge when performing a compression test on a junk yard

motor is that a starter must be bolted up to the engine to spin the engine fast enough to perform the compression test.

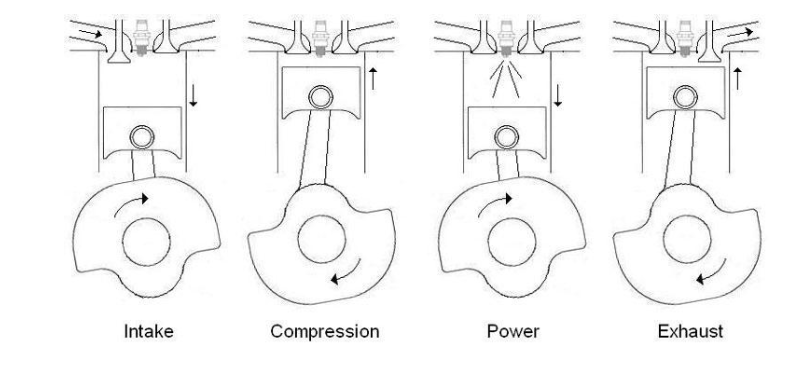

A different way to test a junk yard engine is to perform a leak down test. A leak down test does not require that the engine is warm or turning the engine with a starter motor. The leak down test still takes about the same amount of time to perform as a compression test since the spark plugs must be removed. In the case of a junk yard engine it is relatively faster to remove the spark plugs and perform a compression test because the fenders and firewall are not blocking access to the spark plugs. The point of performing a compression test or leak down test is to ensure that the engine will make good power on all cylinders and that it will not burn too much oil. It is well worth the trouble to test a junk yard engine before spending the time and money needed to install it into a vehicle.

Any factor that keeps the cylinder from filling with air and sealing during the compression stroke, will cause low compression. Common causes are damaged intake or exhaust valves, worn or broken piston rings, scored cylinder walls, a blown head gasket, broken connecting rods, or a hole in a piston. Performing a cylinder leak down test will help find a cylinder with low compression and help to determine the cause for low compression. More on how to perform the leak down test later

Snap on Leak down tester shown below